About Us

Example Of About Us PageCompany History

B&B Iron Works was incorporated in 1982 by Mauro Belgiovine in Hoboken, NJ. Mauro began the business by fabricating small miscellaneous metals projects such as railings and fire escapes for buildings in the Hoboken/Jersey City area. In 2000, the company relocated to a larger shop of roughly 25,000 square feet located in Irvington, NJ. During this time, work volume greatly increased and the average project fabricated weighed in at approximately 800 tons. This work was performed with the aid of automated machinery such as a beam line and anglemaster. In late 2014, the company expanded again to its present location at a 70,000 square foot state-of-the-art facility in Clifton, NJ.

B&B Iron Works was incorporated in 1982 by Mauro Belgiovine in Hoboken, NJ. Mauro began the business by fabricating small miscellaneous metals projects such as railings and fire escapes for buildings in the Hoboken/Jersey City area. In 2000, the company relocated to a larger shop of roughly 25,000 square feet located in Irvington, NJ. During this time, work volume greatly increased and the average project fabricated weighed in at approximately 800 tons. This work was performed with the aid of automated machinery such as a beam line and anglemaster. In late 2014, the company expanded again to its present location at a 70,000 square foot state-of-the-art facility in Clifton, NJ.

The current facility houses 10 overhead cranes with an overall lifting capacity of 100 tons and a maximum single lift capacity of 35 tons. It also features numerous automated CNC machines including multiple beam lines, a plasma plate processor, a cambering machine, and much more. The shop’s unique layout and truck runway also allow for the simultaneous fabrication of several projects and its central location allows easy access to New York and other major cities. In addition, most of the staff have been with the company for many years and have the experience necessary to keep projects moving on a timely and cost efficient basis. All of these advantages have made B&B a premier steel fabricator in the NY/NJ tristate area, capable of fabricating projects in excess of 5,000 tons.

Quality is a Team Sport

Meet The Team

Our company's greatest asset is not its state-of-the-art facility or high tech equipment, but its employees. The men and women who make up B&B work hard every day to ensure that each project is carried out with precision and attention to detail. All of the technological advancement that the industry has to offer would not be enough without a knowledgeable and skilled staff. That is why B&B takes great pride in the technical expertise and education of its employees. All of our estimators, detailers, and project managers have at minimum a Bachelor of Engineering degree, with several Master's degrees as well. Our shop personnel also have decades of experience working on complex projects, with most of them spending their entire careers at our company. In addition, all employees receive ongoing mentorship and periodic documented training by a senior staff member to further their proficiency. When you contract B&B Iron Works for your project, you can rest assured that it will be placed in good hands.

Our company and staff possess the following certifications and qualifications:

- AISC Quality Certification

- AWS Certified Welding Fabricator

- All welding personnel are AWS D1.1 certified

- Multiple staff members with Bachelor/Master of Engineering degrees

- Staff trained in OSHA 30-Hour Safety Training

- New Jersey DPMC Qualification - $45 million

- Bonded for $45 million in total work and $20 million per project

Services

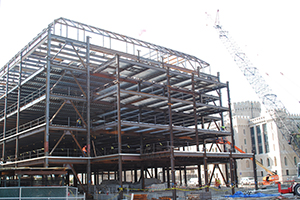

Structural Steel Fabrication and Erection

With multiple drill lines and saws and 100 tons of crane capacity, our facility is equipped to handle the heaviest and most complex steel structures with fast-track schedules.

Miscellaneous Metals Fabrication / Installation

All stairs, rails, and other miscellaneous metal items are fabricated and installed by in-house personnel with years of crafting experience.

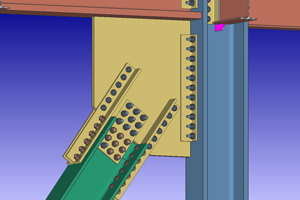

Detailing / Engineering

Our capabilities include 3D modeling, engineering calculations, and programming CNC files for production.

Beam Cambering

Our CAMBCO Model 1700 machine allows us to camber some of the heaviest rolled sections in the industry: up to W40x397 or W36x441

Plate Bending

Our brake press from Primeline enables us to bend plates of up to 3/4″ in thickness.

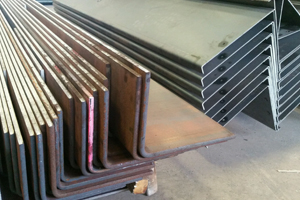

Automated CNC Processing of All Structural Shapes

Using programmable CNC files and state of the art machinery, B&B is capable of processing steel with extraordinary precision and speed. This includes all structural shapes such as wide flange beams, HSS, channels, plates, and angles.

Project Expertise

On any large-scale construction project, challenges and unforeseen circumstances are bound to develop. Managing and mitigating these risks is what B&B’s team excels at. We do more than just fabricate steel. Our goal is to ensure that the project will run smoothly and efficiently for our clients. Below are some examples of our team’s flexibility and coordination practices.

- – The Challenge – The entire perimeter of this six-story building is enclosed in precast concrete panels supported on the structural steel framing.

- – The Solution – B&B worked closely with the GC, Engineer of Record, and precast concrete contractor to lay out and detail all of the various connection components required to support the precast panels. This included HSS bearing outriggers, lateral tie back connections, and diagonal bracing. All of these elements were then incorporated into the 3D BIM model for review by all parties prior to fabrication. This allowed all project team members to identify and remedy any potential clashes or installation issues, allowing erection of steel and precast in one continuous operation.

- – The Challenge – The multiple buildings on this project were engineered using a composite design consisting of steel columns/girders, structural concrete slabs, shear walls, and an Ecospan composite floor system.

- – The Solution – Fabricating and erecting this type of design required extensive coordination between B&B, our joist and deck subcontractor, and other trades such as the concrete, MEP, and carpentry contractors. To ensure that this coordination process was effective, all information was documented and also incorporated into our 3D BIM models using SDS/2 and Autodesk BIM 360 per our company’s standard protocol. Erection of each floor was phased since the steel on the upper levels is partially supported on concrete and light gage elements below. The result was a seamless flow of construction activities between each floor and each building.