Our Facility

State-of-the-art fabrication capabilities in our 70,000 square foot AISC certified facility

Located in Clifton, New Jersey, our facility combines advanced technology with skilled craftsmanship to deliver exceptional steel fabrication services. From initial design through final delivery, every aspect of our operation is designed to ensure quality, efficiency, and customer satisfaction.

Our central location in Clifton NJ provides us with easy access to major highways such as I-80, I-287, I-280, Route 3, Route 19, and Route 46. We are only a short drive from New York City and other major urban centers in the tristate area.

Prior to relocating to our present 70,000 square foot facility, our team met with consultants to analyze potential layouts of the equipment and workstations. The chosen layout achieves an unparalleled work efficiency and optimizes the flow of material through our shop. The multiple bays in our facility are set up to enable simultaneous fabrication of several projects at once with no choke points in workflow. An interior runway allows several trucks at a time to load and offload material.

The shop is outfitted with numerous high-speed CNC machines such as drill lines, angle lines, a plate processor, and bandsaws. Each bay is also equipped with multiple heavy duty overhead cranes that add up to a total lifting capacity of 100 tons, with a maximum single lift of 35 tons. These features allow B&B to process and deliver steel in much shorter time windows than many other firms.

Our 70,000 square foot fabrication facility in Clifton, New Jersey

As an AISC Certified Fabricator, B&B Iron Works is held to a high standard of quality on all of our projects. Participating in this program requires that we maintain an internal Quality Control Program and are subject to an annual on-site audit performed by an outside agency hired by the American Institute of Steel Construction. B&B endeavors to exceed the requirements of AISC and has established measureable goals to continually improve on our commitment to quality.

Careful attention is paid to fabrication details such as preheating requirements, welded joint preparation, weld quality, surface preparation/coating, and final inspection. All of our equipment receives regular documented maintenance and calibration, from the most sophisticated machinery down to individual measuring tapes. In the office, our dedicated staff use the latest software for project coordination, tracking material, and programming CNC files for fabrication machinery. These practices ensure that every project achieves the highest measure of quality, timeliness, and efficiency.

Our rigorous quality control process ensures every project meets AISC standards

B&B is committed to ensuring that only the highest quality weldments leave our facility for the jobsite. It is more than our reputation at stake. The safety of the public also depends on the structural integrity of our product. That is why we hold our welders and weld inspectors to strict standards.

Our welders are certified per AWS D1.1 and receive periodic documented training by a Certified Welding Inspector. Each welder maintains a copy of the AWS D1.1 Manual tables for preheating requirements as well as copies of our in-house welding procedures. All welds are visually checked and recorded during our In-Process and Final Inspections and all full/partial penetration groove welds are ultrasonically tested in the shop by our CWI. These practices ensure that when our steel arrives at the jobsite, it is ready for erection with no mishaps or delays in schedule.

Our certified welders follow strict AWS D1.1 standards with CWI oversight

Our facilities are equipped with the following equipment and capabilities:

- Peddinghaus PCD-1100/C Drill Line in tandem with DG-1250 band Saw

- Peddinghaus PCD-1100/B Drill Line in tandem with DG-1100 band Saw

- Peddinghaus HSFDB-2500/C Plate Processor

- Peddinghaus 623M AngleMaster

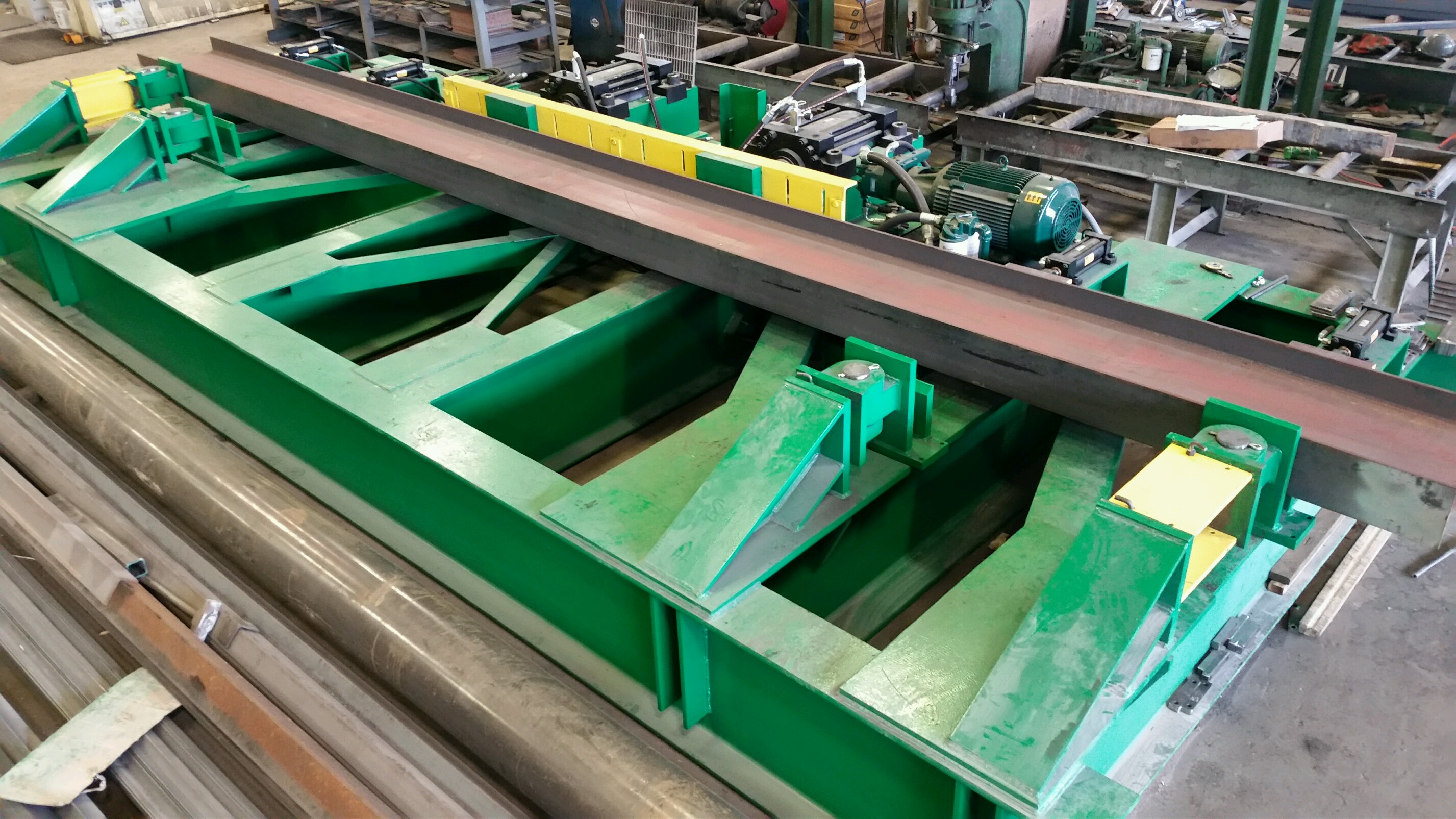

- CAMBCO Model 1700 Cambering Machine (can process up to W40x397)

- GEKA 220-Ton Ironworker Machine

- 105-Ton and 100-Ton Peddinghaus Ironworker Machines

- Hyd-Mech M-20P Band Saw

- Baykal Plate Shear Machine

- Primeline Brake Press Machine for plate bending

- Portable punch machines

- Multiple plasma and welding machines

- Ten overhead cranes with total lifting capacity of 100 tons and max single lift of 35 tons

- 70,000 square feet of enclosed fabrication space

High-Speed Drilling and Saw Cutting

Our multiple drill lines with band saws in tandem can make quick work of large scale projects.

Plasma Cutting

Our automated CNC plate processor can punch and cut plates with exceptional speed and precision.

Beam Cambering

In-house cambering of shapes up to W40x397 or W36x441.

Heavy Duty Fabrication

We have the capacity, manpower, and experience to fabricate the largest of structural assemblies.